Stöger 360°

Technical Consulting

Proof of concepts

Products and solutions

Aftersales and Service

Fastening Solutions

FLEXIBLE. INDIVIDUAL. CUSTOMIZED.

Technical Consulting

We support you in the beginning of your R&D, machine or production project with information, state of the art solutions and gathered knowledge of up to 40 years.

Proof of Concept

We will check, analyze, and scale your requirements (parameters, 2D drawings & 3D, step files) into reports and develop an offer for your value-needs.

Products and Solutions

Together with you we optimize and customize our products to the right fitting solution for your exact needs.

Aftersales & Service

With our 360° Aftersales you get from best Start-Up, Application- to Online-Support and right handling of Spare parts for your maintenance planning.

WE PROCESS

and many more ...

Products & Solutions

Our systems are designed to adapt - whether it’s your process, space constraints, or specific industry requirements.

Thanks to our modular system architecture, we can offer scalable configurations that integrate seamlessly into your production environment without compromising performance.

Contact Us

Every project deserves individual attention.

We work closely with your team to understand your goals and challenges, ensuring that our approach reflects your unique needs — not a generic standard.

Contact Us

True customization goes beyond just options and settings.

At STÖGER, it means purpose-built systems based on a modular foundation, precisely tailored to your application.

From hardware to control logic, everything is engineered to fit — perfectly.

Contact Us

System Solutions

Our system solutions offer easy integration and fast commissioning. Thanks to automated process control, they ensure maximum efficiency and reliable results.

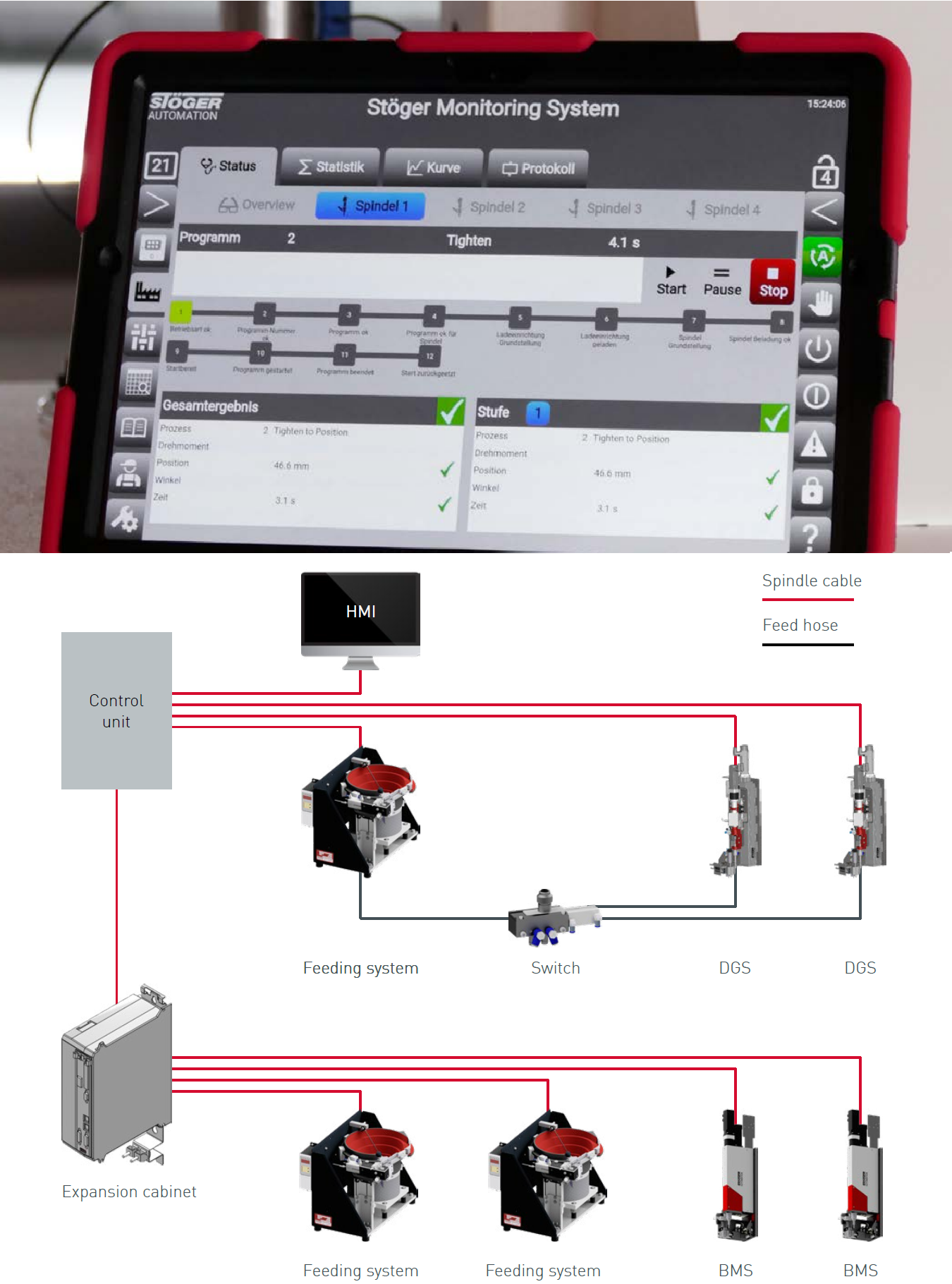

STÖGER Monitoring System - Sequence Control Unit

The STÖGER Monitoring System (SMS) is your single control/monitoring layer for every STÖGER device—capturing, storing, and analyzing all process data for full traceability.

Its modular design lets you combine tools and feeders in one cabinet or cell, scaling as needed.

Why one SMS covers everything

-

Control up to 4 screw spindles and 4 feeding units per SMS—mix, match, and run in parallel.

-

Native I/O plus optional fieldbus (Profinet, Ethernet-IP, etc.) for quick PLC integration.

-

OPC-UA/MQTT connectivity for seamless MES/IT data exchange.

-

Built-in process and curve logging, logbook, and user rights; optional quality data interface.

-

Web visualization (up to 4 clients), integrated 10.1” panel, and handheld—use any combo you like.

-

Remote maintenance boosts uptime; safety standards respected.

Result: One SMS runs mixed STÖGER solutions in a single control unit—simpler integration, fewer cabinets, unified data, and audit-ready documentation.

Wire Thread Insert Screwdriving System

Enables the precise placement of all major insert types

The STÖGER Wire Thread Insert Screwdriving System (DGS-Evo) is a fully automated system specifically developed for installing wire thread inserts (e.g., HELICOIL®) in series production. This technology is increasingly used in the field of GigaCasting & Unicasting. It enables fast, precise, and process-safe installation of these inserts directly from bulk material, without the use of magazines or strips.

Key Features:

- Integrated system technology: Includes feeding and control systems

- Modular design: Reduces spare parts costs and total cost of ownership (TCO); simplifies staff training

- Electric axial drive: Accurate depth measurement and maximum speed for highest quality with short cycle times

- 200 mm tool overtravel: Also reliable for difficult-to-access positions

- Intuitive process adjustment: Simple setup via HMI – individually configurable

- Oriented feeding: Secure and precise positioning of wire thread inserts

- Performance on demand: Expandable system architecture for maximum future security

- Flexible use: Can be integrated directly on a robot or as an external tool

Setting & riveting:

Special requirements: Automated processing with know-how

High demands have to be met when it comes to automatic setting and riveting applications. A variety of machines specially designed for setting, pressing or riveting of almost any kind of fasteners complement the STÖGER product range. No matter which application, all STÖGER models for setting or riveting tasks convince through their properties - time-saving due to short cycle times, easy handling and servicing, highly reliable due to superior technology and by maintaining and monitoring quality parameters. Equipped with automatic feed and control units, STÖGER setting and riveting systems meet the requirements of advanced assembly systems.

Your advantage:

- Checking of the functionality of the thread during spindling on and off, defectively detected rivets are automatically ejected and replaced

- STÖGER positioning compensation ensures exact positioning in the workpiece, patented 6-edge finding method

- 100 % success control thanks to force and distance sensor

- Commercially available standard screw as drawing tool, automatic breakage detection, tool-free changing of the drawing tool possible in 10 seconds

Demand-Oriented Flexibility Products & Solutions

At STÖGER Automation we work with global OEMs and Machine Builders, needs shift and applications change.

Therefore we adapt to your needs with full flexibility.

We deliver a fully pre-engineered package: a spindle/tool head with integrated drive, a matched feeding system, and a sequence control unit that orchestrates feeding, tightening, and end-to-end process monitoring.

Your master PLC connects via your preferred interface, and we provide all required signals plus quality-relevant data for traceability and documentation.

Contact UsKeep control in your Master PLC while we supply a ready-to-mount package: a spindle/tool head with integrated drive, a matched feeding solution, and built-in tightening/process monitoring. We provide a clean I/O or fieldbus interface so your PLC handles sequence and safety, and we hand over all quality-relevant data for full traceability.

Contact UsMaximum flexibility—buy exactly what you need (feed unit, spindle, accessories) and handle the integration, sequencing, and controls in your own PLC. We supply grafcets, interface specs, and support on request.

Only single spindles or feed units, no single components

Contact UsAutomatic Tool-Changing Solution for Multiple Types of Fasteners

Pick and Place System

Maximum flexibility for automated screwdriving processes: The modular Pick & Place Solution with automatic tool change and integrated fastener feeding is ideal for lightweight robots with a payload starting at 3 kg. Its modular design allows for flexible combinations of screwdriving tools and grippers within the tool change system – enabling highly adaptable assembly processes.

Your advantages:

- Modular system

- Flexible system layout

- Various tools adaptable (nose pieces, grippers)

- High savings potential

- Multiple work steps can be carried out with one

system - Simple system expansion

- Encoder checks whether the correct tool is

taken (optional) - Can be operated on different robots and axis

systems - Various drives available on request

Automatic Screwdriving Systems

Assembly automation for series production

STÖGER automatic screwdrivers and feed units with integrated control units provide sophisticated technical features that make them stand out as economic and easy-to-operate tools in the automation sector. Our screwdrivers ensure results that can be documented and thus guarantee high efficiency and serviceability, which makes them highly suitable for a wide variety of possible applications in series production and for customised assembly automation in plant engineering.

Your advantage:

- short cycle times

- easy to service due to superior design

- reliable even under constant operation in series production processes due to advanced technology for >10 years

- high technical availability due to quick tool change

- different drives with or without process analysis possible for fitting the companies preference

- GAP Control measuring tool for checking the screw head contact to work piece surface

- different features to assure >99,9% process reliability independent of the fastener dimension and shape

Feed Units

precise and fast: automatic feed systems by STÖGER AUTOMATION

No matter which connecting element: STÖGER feed units ensure a trouble-free supply of the fastener to hand-held screwdrivers, automatic screwdrivers and other systems at any time. Our feed systems advantageously operate with short cycle times of up to 100 fastening elements per minute. Depending on their properties our prime quality systems come in various sizes, capacities and models. They provide a fill level control and a hopper for automatic refilling of the system, as well as a detachable acoustic cover for reducing the noise level and ensuring quick access.

Your advantages:

- distance between screwdriver and feed unit of more than 20m possible

- acoustic cover for noise reduction, detachable for quick access

- singling mechanism: smooth transfer between output rail and single screw selecting mechanism

- extremely efficient due to quick tool-free maintenance

- high cycle times of up to 80 fasteners per minute

Applications & Industries

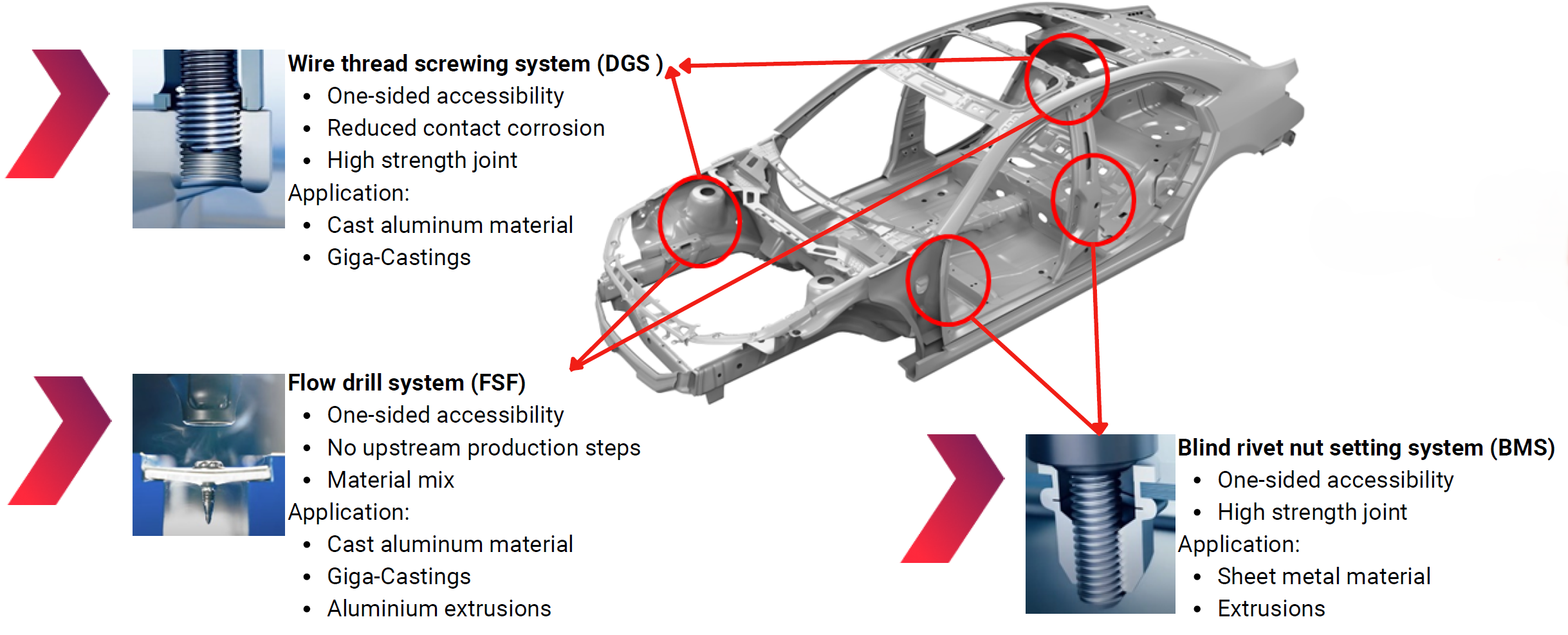

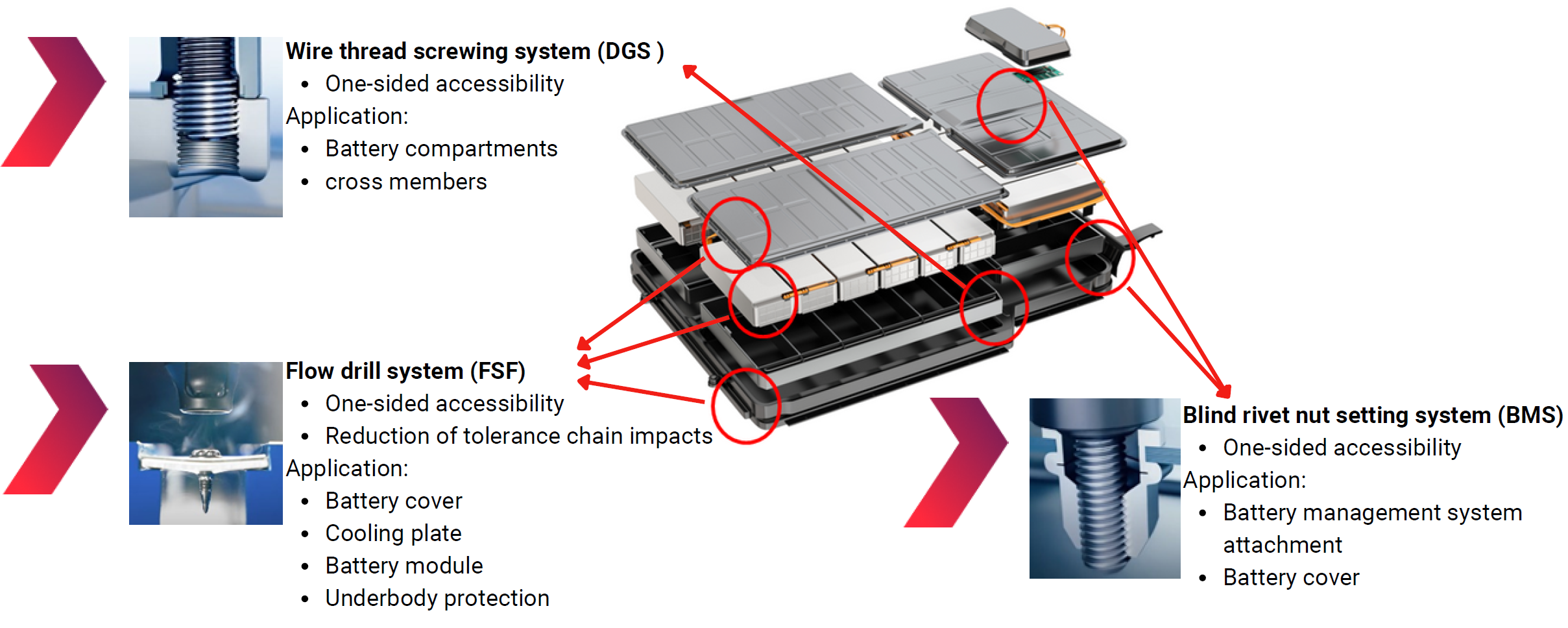

Solutions for Lightweight Car Body Assy

FSF: One-sided, no pre-drill; ideal for mixed materials and castings. Edge: Modular autofeed, PLC-ready, monitored, traceable.

BMS: One-sided robust threads in sheet/extrusions. Edge: Robot-ready blow-feed, force–stroke control, clean data handoff.

DGS: Strong, corrosion-conscious threads in cast parts. Edge: Torque/angle & depth checks, quick changeover.

Solutions for Battery Pack Assy

FSF: Simplifies large covers/baseplates. Edge: High-speed autofeed, full traceability.

BMS: Reliable threads for lids/service points in thin sheet. Edge: Compact tools, pick-and-place option.

DGS: Suits sealed housings and structural members. Edge: Presence/length checks, standard interfaces.

Contact

Alessandro Eggert

President

Address

150 North Michigan Ave., 35th Fl.

Chicago, IL 60601

Tel: +1 312 794-8525

Mobile: +1 312 998 0455

Distributors & Manufacturers Reps.

Automation Technology Sales, LLC

Address

1172 Callis Road

Lebanon, TN 37090

USA

Tel: +1 615 406 6799

Mail:

Carolinas mlawson@autotechsls.com

Alabama, Tennessee cwebster@autotechsls.com

Website: HOME | Auto Tech Sales

AWP Motion & Safety, LLC

Address

800 Wacker Dr.

Dubuque, IA 52002

USA

Tel: +1 563 207-8746

Mail: office@awpmotion.com

Website: Integrated system – AWP Motion

MEI Representaciones

Address

Lorenzo Angeles 92-6, Col, El Pueblito

76900 Santiago de Querétaro

Querétaro

Tel: +52 442 828 82 71

Mail: ventas@meirepresentaciones.com

Website: Conectamos la mejor tecnología con tu industria | MEI Representaciones

About the Company

STÖGER AUTOMATION GmbH is a specialist for fastening technology. The family-owned company was founded in 1987, is in its second generation and occupies a leading position in the automation technology segment.

At the company headquarters in Königsdorf, Upper Bavaria, >130 employees develop and manufacture high-precision fastening solutions from screwdriving, setting units with automatic feeding of the fasteners to highly customized solutions. The developments hold over 30 patents. More than 13,000 solutions are in use in all industries - exactly where precision, speed and consistent quality are required.